The Zilwaukee Bridge: From the Beginning

The following pages reproduce a 1987 report issued by the Michigan Department of Transportation in response to public concerns about the safety of the Zilwaukee Bridge, then nearing completion. The text here is reproduced word-for-word from the original report and no alterations—grammatical or otherwise—have been made. |

THE ACCIDENT

Erection of the segments started in 1981 at the north end of the northbound bridge and proceeded southward. By August 1982, all 52 piers needed to support the bridge had been completed by Toebe Construction Company and 13 of the 25 spans on the northbound bridge had been completed by Stevin. The launching girder was standing on partially completed spans at piers 11, 10 and 9.

Each of the two bridges has eight expansion joints that allow the decks to expand and contract with changes in weather temperatures. Erecting the spans of the bridge that contain expansion joins poses unusual challenges. During constrcution, the expansion joints must be firm and restrained from any movement, like all other segments. After a span is complete, the joints must be able to expand and contract.

Conversion from rigidity to expandable behavior is accomplished by inserting temporary blocks specially cast of high-strength concrete into the expansion joint. The blocks are held tightly in place by temporary steel tendons. After the span is complete, the blocks and the tendons are removed and the joint is free to move.

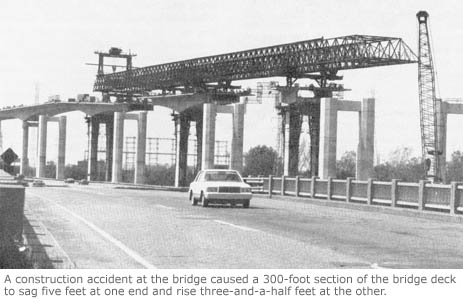

Prior to August 1982, four expansion joints had been constructed without experiencing any problem. But on August 28, the temporary compression blocks in the expansion joint in span 11 on the northbound bridge began to crush while a concrete segment was being transported by the launching girder. This caused a 300-foot-long section of the bridge deck to sag five feet on one end and rise three-and-a-half feet at the other.

The tilting of the deck section caused considerable damage. The top of pier 11 was forced about eight inches out of plumb, damaging the pier footing. The movement ruined the bearings, made of stainless steel, neoprene and teflon, and placed between the piers and bridge deck to accommodate motions caused by traffic loads and temperature changes. The upward deflection of the expansion joint caused some of the segment joints and the expansion join to open. Crushing of the top-slab concrete at the expansion joint also occurred.

The cause of the accident was far from simple. As the U.S General Accounting Office pointed out at the conclusion of its inquiry into the incident, there were five separate contributing factors. The base cause, however, was construction loads at that particular location which were too heavy.

Next: Section 5: Making Repairs

Back to: Section 3: Bridge Technology

Back to: Table of Contents